What is the future of 3D printing in fashion?

Today, when we talk about print in fashion we don’t talk about paper, we talk about 3D, a three-dimensional object.

The first paper printing machine was created almost five hundred years ago and came to change the world. However, what we have seen in the last decades in the printing industry will revolutionise the way we see the future. This technological innovation has marked a difference for almost every industry, and the textile industry is no exception.

Although I still find it difficult to understand how a digital machine can create a solidified 3D piece, I am here to tell you how 3D can be used in fashion, how computer controls can take over traditional design and manufacturing practices, or at least, try to.

First of all, this design technique can help in the stages of prototyping and sampling. It allows design teams to prototype and visualise a garment prior to their production, which allows resource efficiency and time reduction. This gives time to the designers to act more freely, take more risks and work with more than one prototype, since paper and fabric are not needed. It also allows the avoidance of waste in pre-production, hence, sustainability.

Moreover, in the buying and selling stage, the sustainability aspect can be maintained. This is because there is a possibility of avoiding the production of innumerable garments, and instead, selling the made-to-order product to the client, who can visualise the 3D printed product prior to its purchase. This allows selling exactly what is being bought, and consequently, avoids waste.

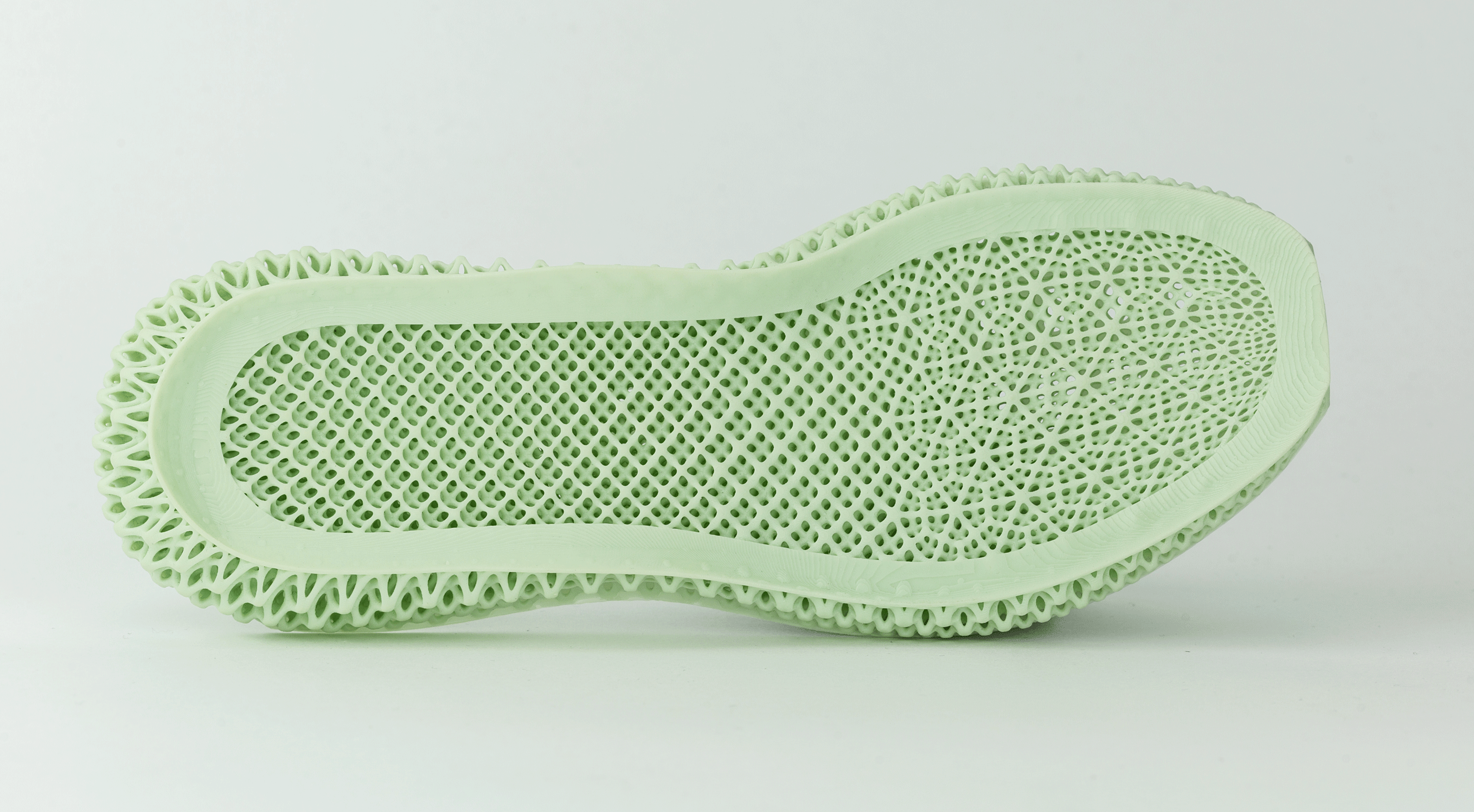

Also, the 3D print stage itself allows the use of materials that require less water than conventional fabrics like cotton, materials that are usually recyclable and reusable. Liquid materials or powder grains are fused together and create more breathable materials than conventional ones.

In addition, it allows local printing, avoiding the shipment of the garment from the other side of the world. Finally, the garment can be customised, which minimizes customer returns, hence, the emissions involved in this stage. Overall, 3D printing can be a route to sustainability in the industry.

However, it is true that although fashion and technology have worked closely in recent years, 3D print wearable fashion pieces are still an exception. Only haute couture or limited fashion pieces are printed to be wearable. A great example, in my opinion, is the designer Danit Peleg and her personalized 3D jacket project. It takes 100 hours to print one of those jackets, so, no wonder why they are limited edition:

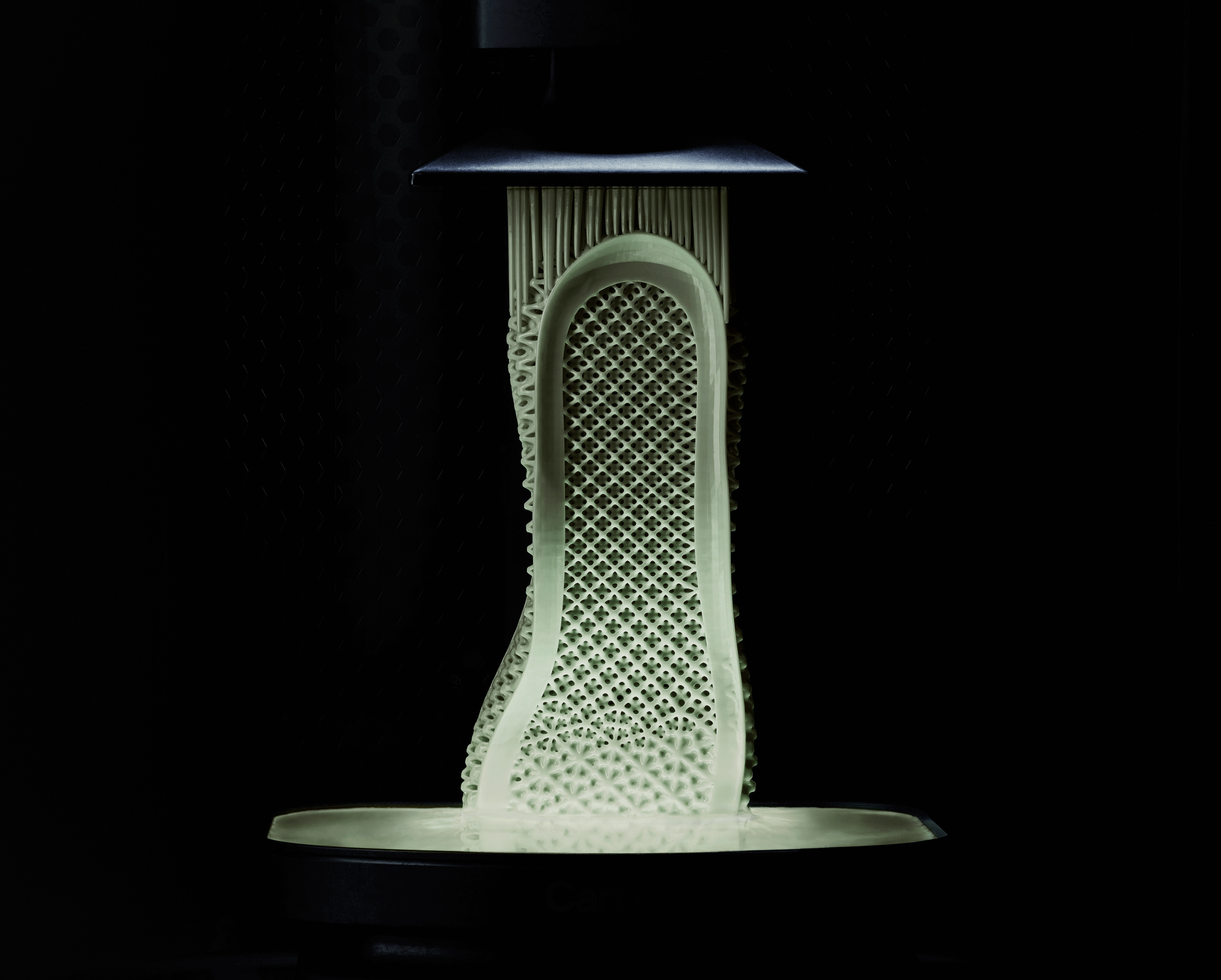

Most usually, 3D print is used as a supplement (not substitute) of fashion manufacturing practices. The journey towards the globalisation of the use of 3D wearables is still a long one. Therefore, this technology is mainly used to produce embroidery, accessories or parts of a fashion product. An example is Adidas 3D printed midsole (a component of the sneaker):

Ddigitt is a consultancy company within fashion driving digital transformation in the industry, with companies like Kering, Emilio Pucci, Fendi or Farfetch on board. This company is, as seen on their website “on a mission to support the fashion industry with the necessary 3D fundamentals to successfully accelerate the supply-chain digitalization process, reducing waste and overproduction”, and they see 3D as the digital opportunity of the decade.

3D print has come to create shapes and geometries that have never been seen before, 3D print has come to make the fashion supply-chain more sustainable, increase efficiency and reduce waste. 3D is here to stay.

Nonetheless, it is also key to note the drawbacks of 3D printing. Whilst the sustainable benefits are numerous, there are also some ‘cons’ in this technique. It is not efficient for large orders, since printing one wearable garment might take up to 100 hours, hence, it is not efficient for the current fashion business model that produces large quantities of garments. Also, it will impact jobs since digital machines will replace jobs in the manufacturing industry, but on the other side, that will create opportunities to grow professionally in the digital sector. Last, but not least, 3D materials are limited compared to current fashion fabrics, so, what will happen to creativity?

However, in this last year, more than ever, 3D has been on the eyes of the fashion industry. This is because it is an opportunity to transition towards digital design techniques remotely. The 3D printing industry has already created fascinating things, but it is still evolving. I can’t wait to see what is next, and hopefully, I will be able to wear 3D garments myself pretty soon.

Check out more fashion content here

![ZINO VINCI’S ‘FILTHY & DISGUSTING’EP BRINGS YOU TO THE CORE OF THE ARTIST [@ZinoVinci]](https://guap.co/wp-content/uploads/2023/10/Zino-4.jpg)